IMA SCREEN GP 5500

Button

IT HAS A SCREEN

TWO-COMPONENT INK TDC 8700

INK TYPE

Two-component, glossy ink for printing in automatic, semi-automatic machines, or manual printing.

TDC 8700 ink resists alcohol, esters, cosmetic products (shampoo, hairspray), detergent, soap, mineral oil and gasoline.

TDC 8700 paint does not resist aggressive aromatic solvents, ketones, aggressive chlorinated hydrocarbons.

APPLICATION

TDC 8700 ink is especially suitable for surfaces that are difficult to print with quick-drying inks, such as: Pre-Treated Polyethylene, Pre-Treated Polypropylene, Polyester, hard PVC, ABS, Polyurethane, Aluminum, Copper, Tinplate, Supports Lacquered, Nylon.

TDC 8700 paint also adheres to various surfaces, such as PVC, without the use of a hardener. MIX 90 parts by weight of TDC 8700 paint with 10 parts by weight of TDC 8700 Normal Hardener.

This proportion can be increased to 70 of TDC 8700 paint with 30 of TDC 8700 Normal Hardener.

However, the more hardener, the less flexible the film will be after curing. Instead of 10 to 30% of TDC 8700 Normal Hardener, you can use 4 to 12% of TDC 8700 Special Hardener. TDC 8700 Special Hardener has the advantage of maintaining the rheological characteristics of the paint.

LIFESPAN

Undiluted and at a normal temperature, the paint/hardener mixture can be used for 120 hours (approximately 1 week). Diluted at low temperatures, the paint will be more durable.

SOLVENTS

TDC Normal Solvent, and can be used up to 10%. In very hot locations, it is recommended to use retarder instead of solvent.

DRYING

TDC 8700 paint dries by evaporating solvents and reacting with hardener.

DRYING TIME

The paint film will be dry on the surface after 10-15 minutes (touch dry), and 24-48 hours in depth (complete cure). Adhesion can only be tested after the film has completely cured (after 24-48 hours).

To obtain immediate adhesion, the surface can be passed in an oven at 100-200°C. Full cure is achieved in 2 minutes at 180°C or in 10 minutes at 100°C.

MILLING

3 to 4 microns.

MIGRATION

There is no risk of migration.

SHINE

All colors will be brilliant after application.

FLEXIBILITY

The flexibility of TDC 8700 ink is excellent. This is important in metal applications, where the metal must be deformed after printing. The paint layer can be applied at a 180º angle without any problems.

WEATHER RESISTANCE

Excellent and superior to the life of the support.

PERFORMANCE

45 m² per gallon, with 120 T screen.

CLEANING THE SCREEN

Solvent of LP U.

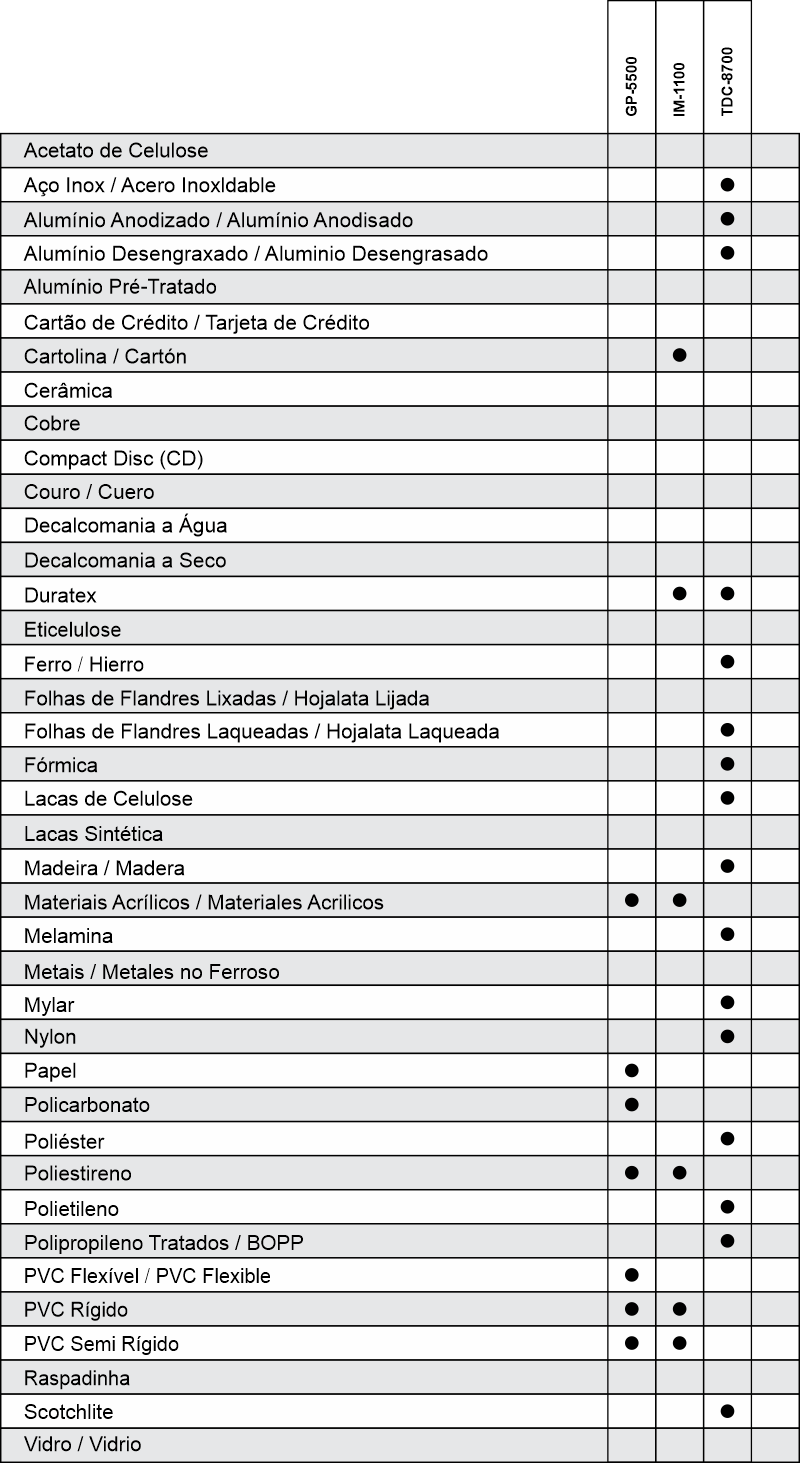

COMPATIBILITY

IMPORTANT:

All information contained herein is the result of our experience and provided in good faith. We suggest carrying out prior tests to prove the effectiveness of the product in relation to the desired results. If you have any questions or suggestions, please contact the Technical Department of Ddgraf Ind. E Comércio De Tintas Gráficas LTDA. REMEMBER: The use of all chemical products within environmental and safety standards shows respect for life.

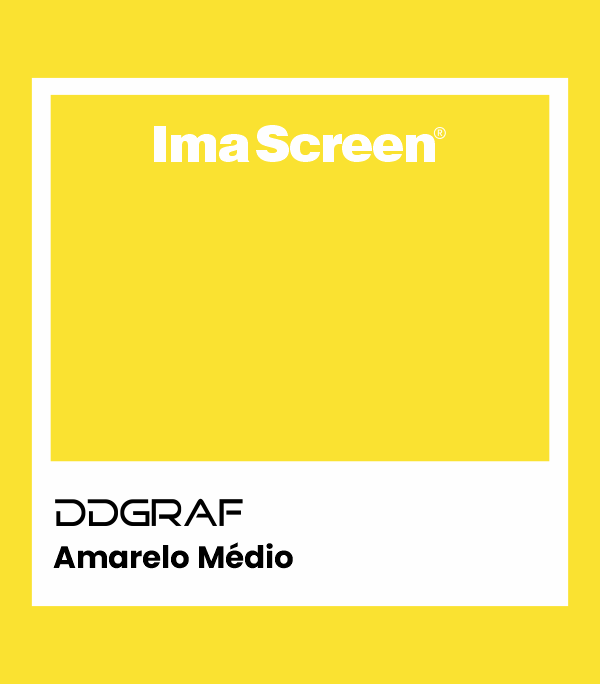

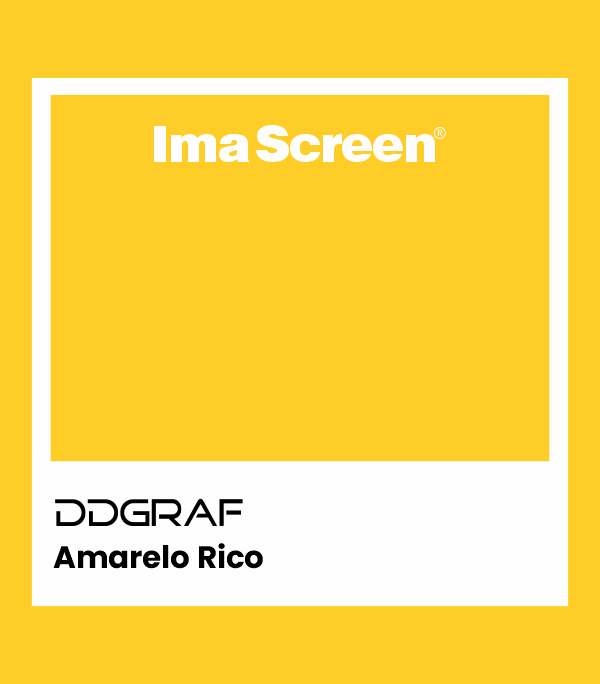

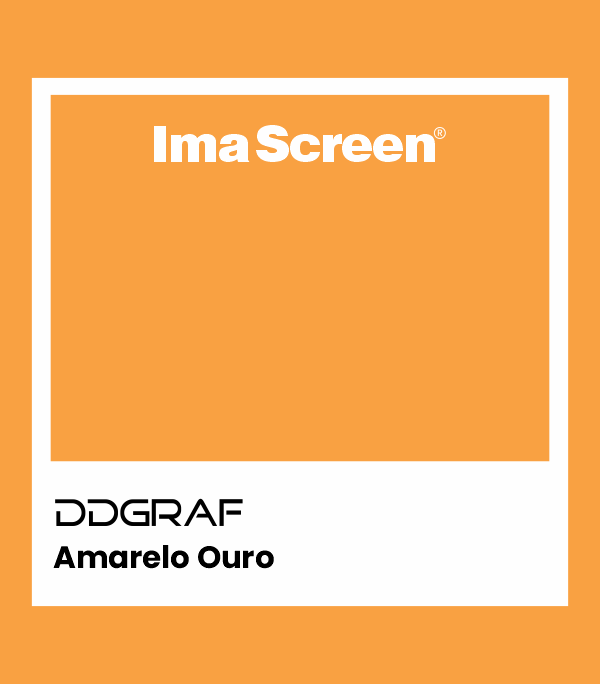

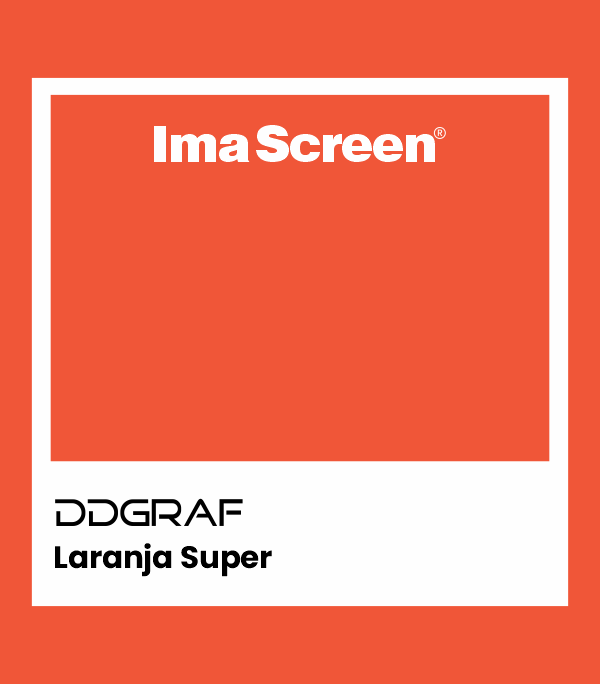

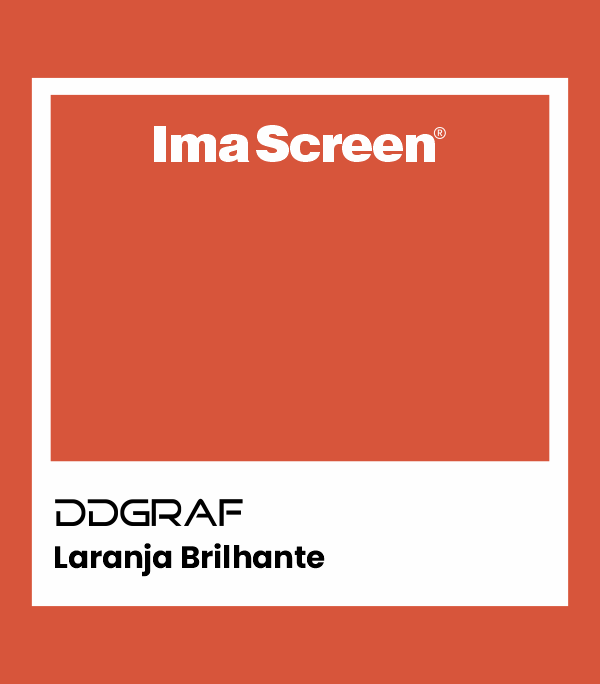

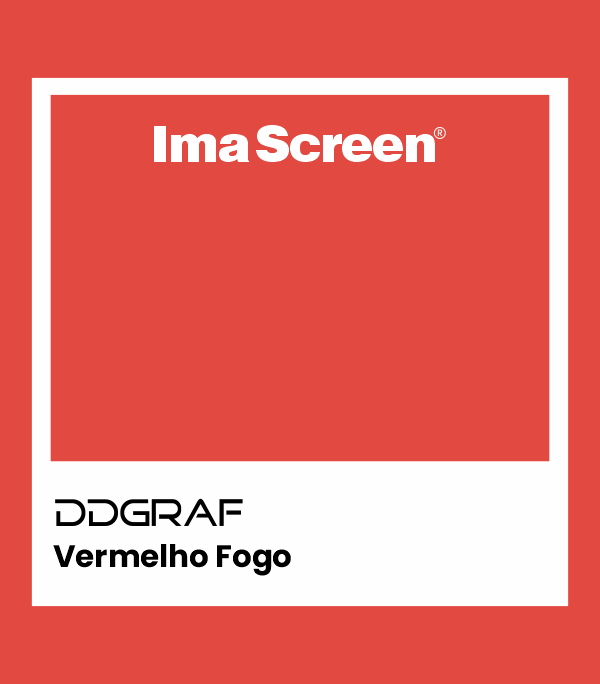

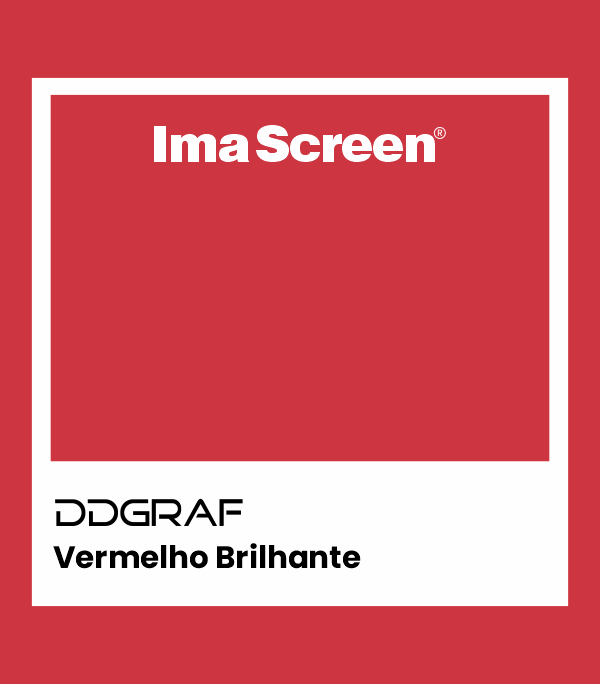

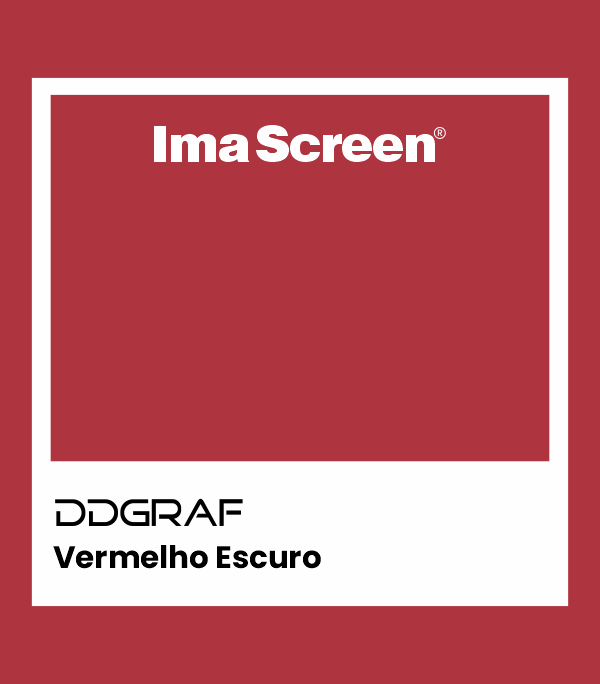

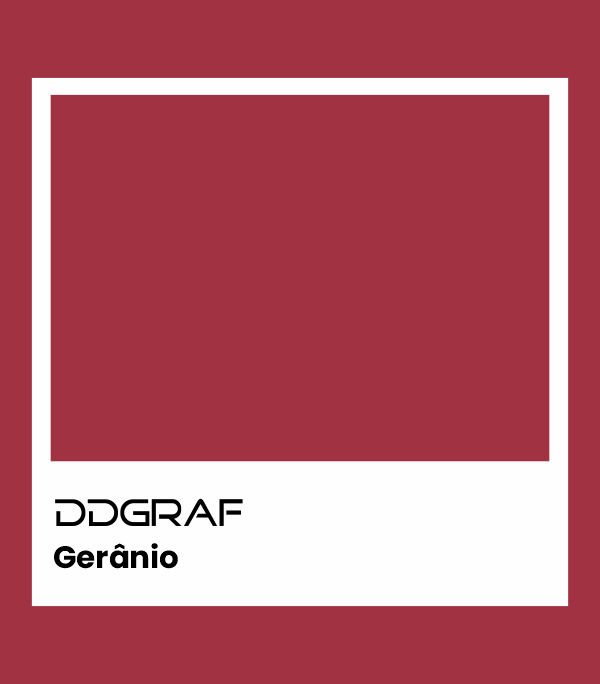

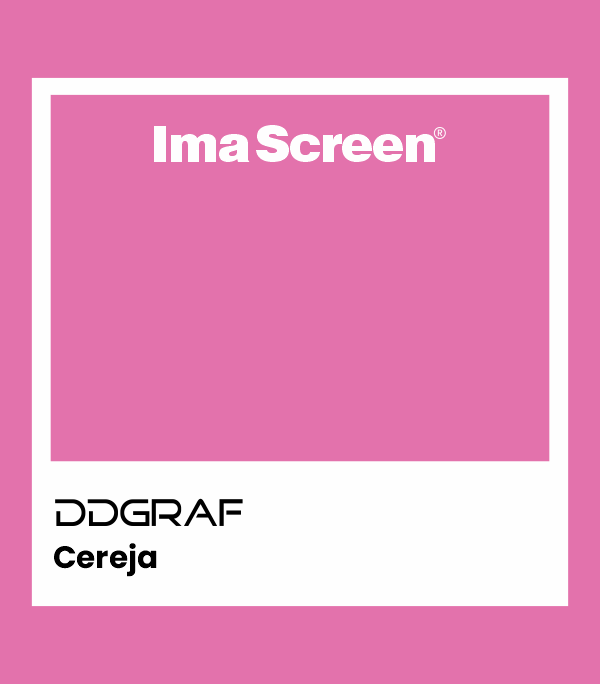

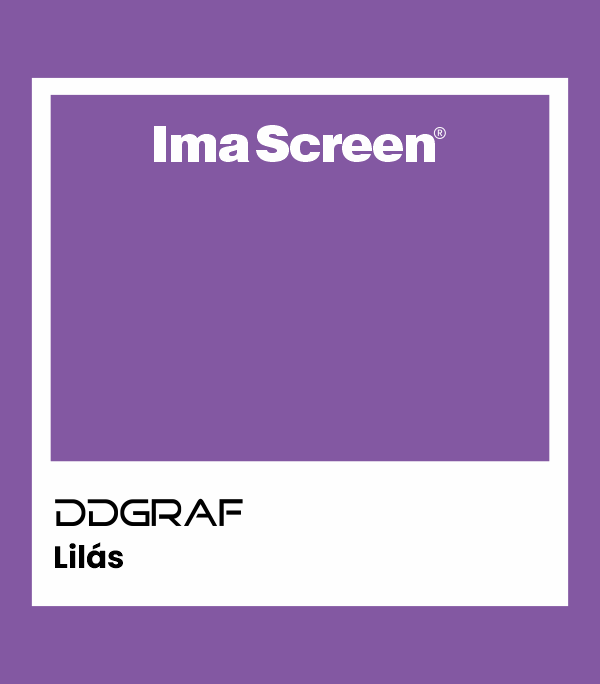

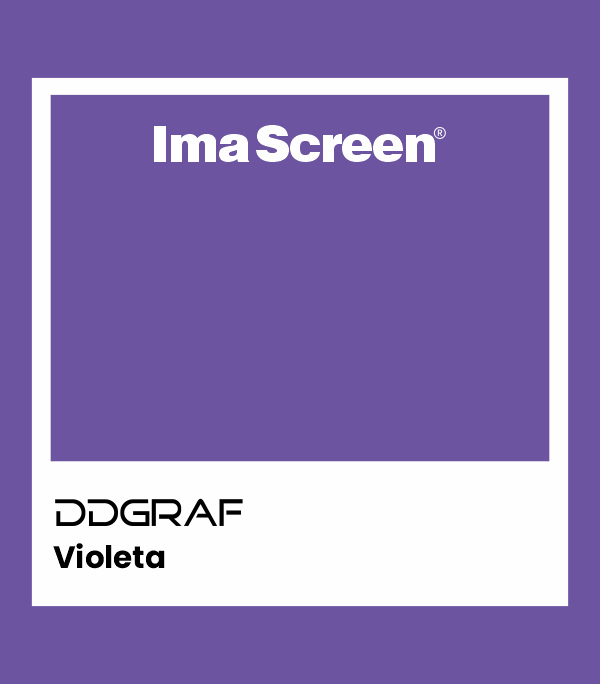

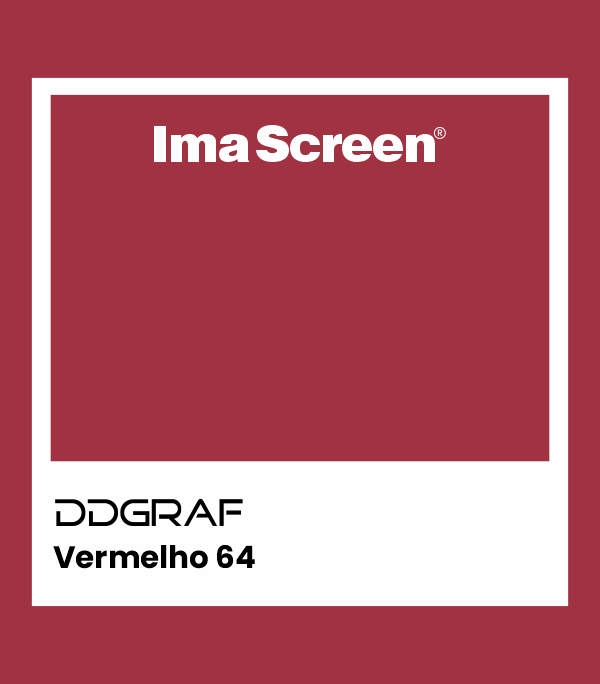

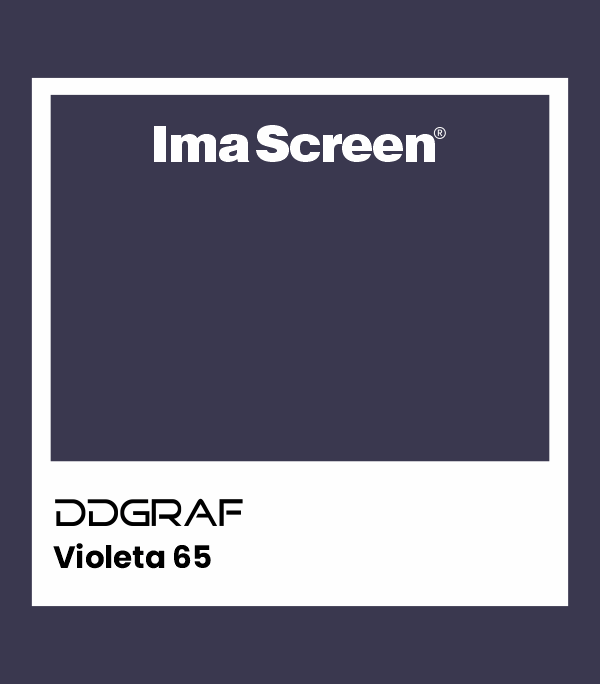

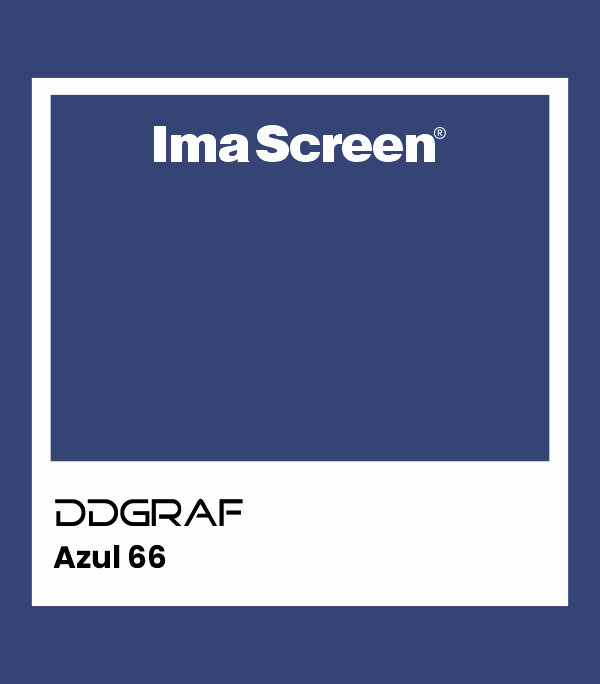

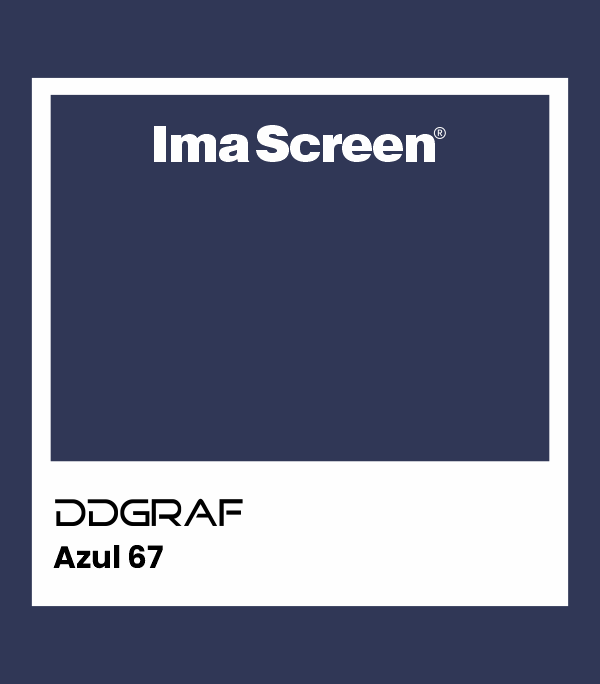

COLOR CHART

*** Product colors may vary depending on your monitor, please request a physical sample ***

FISPQ REQUEST - IMA SCREEN